Of all forming manufacturing processes in the foundry the casting process is the most versatile with regard to freedom of design.

When lost moulds are used in the process, a clay-bonded moulding material is used in most cases.

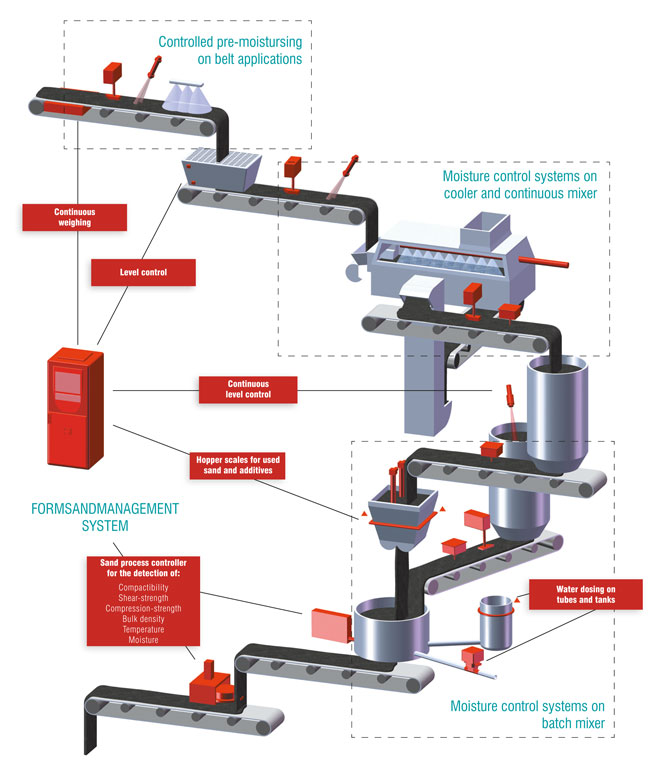

Clay-bonded moulding material is recirculated in the process and requires a reconditioning technology by which the moulding material is cooled-down and moisturised after shake-out and the used-up constituents are replaced in a manner that a moulding material of high homogeneity for the production of new moulds is obtained.

Sensor Control is providing in this field various systems which, based on decades of experience, cover all stages of the reconditioning of clay-bonded moulding materials from shake-out to the moulding machine and which, due to the modular design, can be integrated into any type of sand preparation plant regardless of the mechanical set-up.

Our Products for the foundry industry

Automatic Used Sand Pre-Moisturising FRS-A

Automatic Water Dosing for Knock-out / Cooling Drums FRS-T

Automatic Moisture Control at the Cooler / Continuous Mixer FRS-K

Automatic Moisture Control at the Batch Mixer FRS-M

Automatic Sand Testing Systems SPC

Control Systems for the Sand Preparation Plant

Pneumatic Binder Injection BMI

In-stream Inoculation System PSI

Networking in the foundry industry

For more detailed information, please refer to our information brochures:

Productcatalogue Application Foundry Industry

Characteristic tasks and problems in the foundry management

Questionnaire Formsandmanagement

Download

Download Download

Download